Damage caused by bearing maintenance

The dovetail guide rail sound and control measure raceway sound of the bearing are a kind of continuous sliding sound sent out by the overturning body of non-standard bearing on the surface of dovetail guide rail when the unilateral bearing operates, which is the unique basic sound generated by all overturned bearings. The general inlet bearing sound is the dovetail guide rail sound plus other sounds

How to carry out daily maintenance for deep groove ball bearing

Accumsan euismod per massa malesuada aenean mattis nunc laoreet dictum, nisi vel praesent tincidunt penatibus pellentesque eros duis dis, quam et nascetur id montes…

Which type of bearing has lower noise?

The noise of bearings not only affects the quality of use, but also brings a lot of trouble to mechanical equipment. In general, bearings will produce some noise during use, and the invasion of foreign substances can directly cause the bearing to produce certain noise during operation, or improper lubrication, improper installation, etc. can cause the bearing to emit various noises. Which bearings have lower noise levels during use?

What is a bearing shell? The difference between bearing shells and rolling bearings

In industrial society, bearings are an essential component. With bearings, people can transform one form of motion into another or reduce the friction between two contact surfaces. However, bearings are well-known. Most people may not know about bearing shells. Do you know what bearing shells are? What are the differences between it and bearings? Based on our understanding, what is a bearing shell? What is the difference between bearing shells and rolling bearings?

What are the common wear states of bearings?

Bearing failure is a common problem during the operation of bearings, among which wear is a type of bearing failure, and wear also causes great damage to bearings. If only a few pieces are repaired, it will directly lead to bearing damage and failure. Based on my understanding of bearings, I would like to share several common forms of bearing wear.

How to control the radial clearance and positioning of motor bearings?

The internal clearance of a bearing refers to the total distance that one bearing ring can move radially or axially relative to the other bearing ring. For the clearance of bearings, it is necessary to distinguish between the initial clearance before installation and the working clearance after installation and reaching its operating temperature. The initial clearance of a bearing is generally larger than its working clearance due to the tolerance fit of different interference amounts, as well as the varying degrees of thermal

Proportion of bearing failure modes

During the use of bearings, there are many forms of failure, which can be classified into four types based on the overall situation: improper assembly, improper lubrication, pollution, and fatigue. What is the proportion of these failure modes when bearings fail? Based on experience, share the approximate proportion of bearing failure forms.

Noise inspection and maintenance of thrust ball bearings

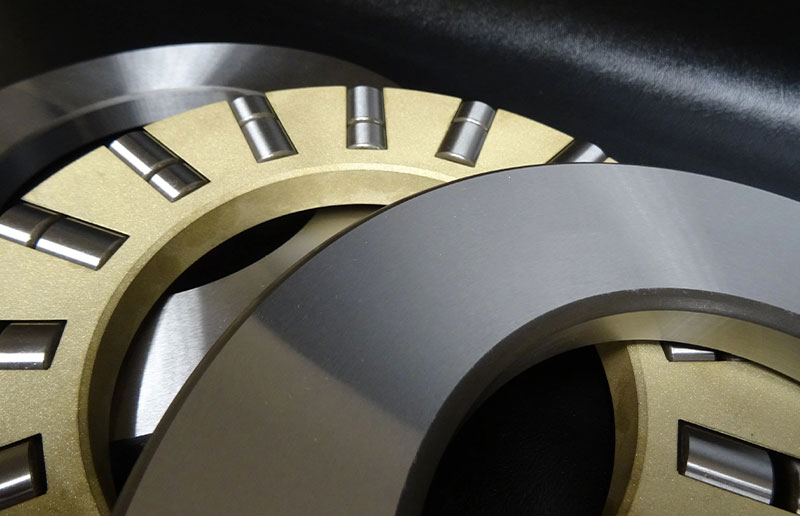

To determine whether the disassembled bearing can be reused, it is necessary to inspect the thrust ball bearing after it has been cleaned. Carefully inspect the condition of the raceway surface, rolling surface, and mating surface, the wear of the cage, the increase in bearing clearance, and whether there is any damage or abnormality related to the decrease in dimensional accuracy.